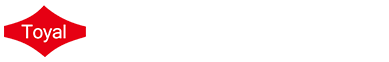

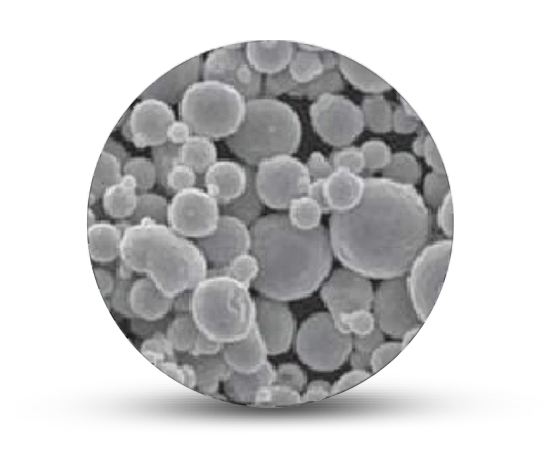

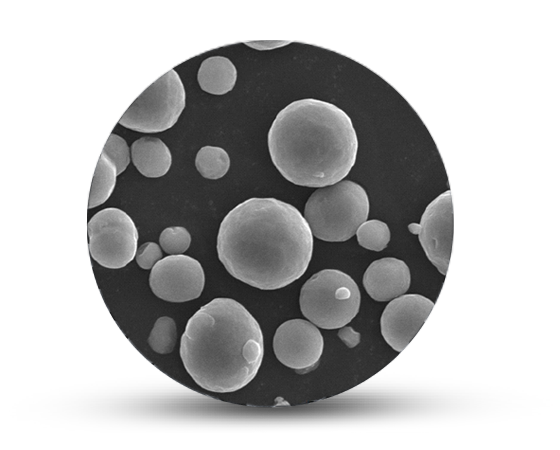

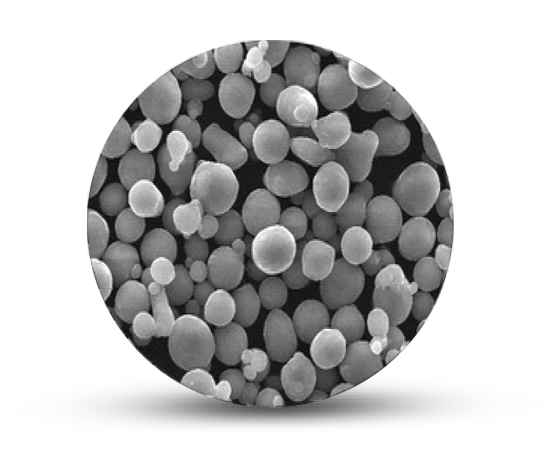

Al-Si-Mg series alloy powder

High sphericity

Low oxygen content

particle size can be adjusted

Key words:

Metal powder

Classification:

Product Parameters

| Product | Chemical Composition | Specifications( μm) | Product Features | Applications |

| AlSi10Mg | You're 9.0-11.0%. Mg≤ 0.25-0.45% Fe ≤ 0.20% |

15-53 | D10: 15~18 ;D50 :30~35 D90: 55 ~ 58 ;O≤ 600ppm Angle of repose ≤41° Loose density: ≥1.3g/ml, Tap density ≥1.6g/ml |

3D printing |

| 20-63 | D10 : 20. 5~23 ;D50:35~40 D90: 55 ~ 65 ;O≤ 500ppm Fluidity ≤24S/50g Loose density≥1.3g/ml Tap density ≥1.6g/ml |

|||

| 0-25 53-150 Others |

Good sphericity Low oxygen content particle size can be adjusted |

Spraying powder metallurgy Others |

||

| AlSi7Mg | Si: 6.5 ~ 7.5%. Mg :0.5~0.75% Over: 0.08-0.25% Fe ≤ 0.20% |

15-53 | D10: 15~18 ;D50 :30~35 D90: 55 ~ 58 ;O≤ 600ppm Angle of repose ≤41° Loose density ≥1.3g/ml, Tap density≥1.6g/ml |

3D printing |

| 20-63 | D10 : 20~25 ; D50 : 35~40 D90: 55 ~ 65 ;O≤ 500ppm Fluidity ≤24S/50g (Hall: Φ5) Loose density ≥1.3g/ml, Tap density ≥1.6g/ml |

|||

| 0-25 53-150 Others |

High sphericity Low oxygen content particle size can be adjusted |

Spraying powder metallurgy Others |

Applications

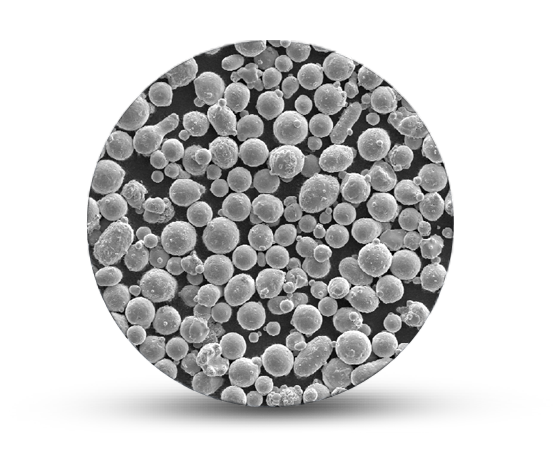

| 3D printing materials | ||

|

|

|

|

Diamond dies

|

Negative electrode materials for lithium batteries | |

|

|

|

|

Powder metallurgy

|

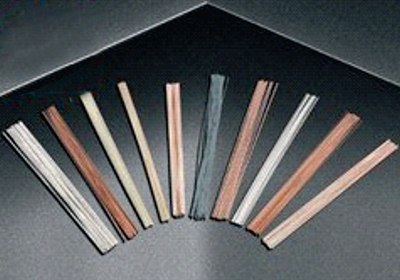

Aluminium-based brazing materials

|

|

Related Products

Welcome your message consultation

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline:+86-0731-87890331